| Payment Type: | L/C,T/T,Paypal,Money Gram |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Piece/Pieces |

| Delivery Time: | 5 Days |

Model No.: TH100-LT

Brand LT

F0/23B

H3/36B

H25/14C

H20/14C

K30/30

H40/40C

Our Products includes the following:

1, Crane accessories

2, Electric Hoist

3, Single - beam cranes

4, Double - beam cranes

5, Bridge Crane

6, Gantry Crane

7.Lifting Equipment and accessories

We supply crane products all over the globe to a wide range of companies worldwide.

Product Description

1.The purchase of hooks shall be used by technical documents such as the certificate of the manufacturer;The lifting hook, such as railway, port, etc., must be strictly inspected (inspection).

2. The lifting hook shall not have any defects affecting the safe use performance;The hook defects shall not be welded;The hook surface should be smooth, no crack, fold, sharp Angle, burr, crack, overburn.

3. Select two suitable positions at the shortest distance of the hook opening to print the non-wearing signs, measure the distance of the sign, and use it as the basis for detecting the change of opening degree in the use.

4. The lifting hook materials can be made of 20 high quality carbon steel or lifting hook special materials DG20Mn, DG34CrMo, etc. It is strictly prohibited to use casting hooks.Plate hook materials are generally used for A3, C3 ordinary carbon steel, or 16Mn low alloy steel

5. The technical conditions of the homemade hooks shall conform to the stipulations of GB 10051-88 ~ GB 10051.5-88 (new standard: gb10051.1-2010 ~ GB 10051.5-2010)

6. The longitudinal axis of the plate hook plate must be in the rolling direction of the steel plate, and the hook plate is not allowed to be spliced.

7. The plate hook and hook plate shall be riveted by the head rivet, and the high-stress bending parts of the hook and lifting objects shall not be connected with rivets.

8. No closed welding shall be allowed between sheet hook lamination, only intermittent welding is allowed.

9. The lifting hook that has already carried over the overload test should be scrapped.

Technical Requirement

1, the purchase of hooks should have the manufacturer's certificate and other technical documents can be used; important departments to purchase hooks such as: railways, ports, etc., hook factory to be strict inspection (testing). Claw hook

2, the hook should not affect the safety performance of the defects; hook defects shall not be welded; hook surface should be smooth, no cracks, folding, acute angle, burr, stripping, burning and other defects.

3, the shortest distance in the hook can be selected at two the appropriate location to print the mark is not easy to wear, measure the distance of the mark, as the use of detection of openness is the basis for changes.

4, hook material can be used 20 high-quality carbon steel or hook special materials DG20Mn, DG34CrMo made of forging, is strictly prohibited to use casting hook. Plate hook materials generally use A3, C3 ordinary carbon steel, or 16Mn low alloy steel

5, homemade hook technical conditions should be consistent with GB 10051.1-88 ~ GB 10051.5-88 requirements (new standards: GB10051.1-2010 ~ GB 10051.5-2010)

6, the hook's vertical axis, must be located in the rolling direction of the steel plate, and the hook does not allow splicing.

7, the hook application head rivet riveting, and in the hook and hanging objects hanging point of contact with high stress bending parts shall not be connected with rivets.

8, plate hook between the film is not allowed to fully enclosed welding, only allowed to intermittent welding.

9, has been carried out on the overload test hook should be used for scrapping.

1. Our History:

LITE Crane Co., LTD has focused on top quality crane parts for over 14 years in China. We started as a small operation, but now have become one of the leading suppliers in the crane industry in China.

Today, LITE Crane Co., LTD has been one of the top producers of quality crane and crane parts, such as: electric hoist, single, double girder bridge, gantry, Grab, casting, explosion-proof crane series and accessories.

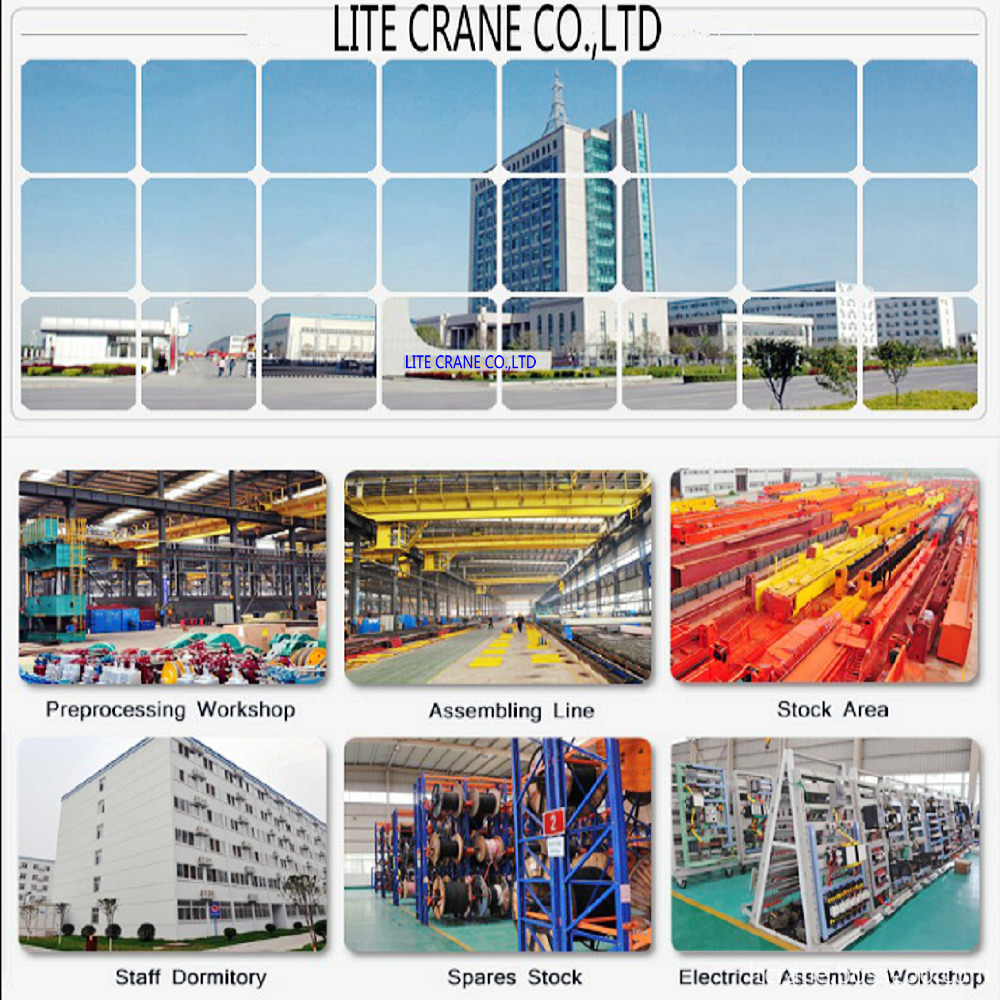

2. Our Factory:

LITE Crane Co., LTD is located in Xinxiang, Henan Province China. The company covers an area of 680 thousand square meters and owns more than 2700 employees. The annual sales of LITE Crane Co., LTD is 1.6 billion USD, there are more than 600 sales agencies at home and abroad and more than 180 middle& senior engineering and technical personnel who are in charge of design and development of all products and also own the development center of their new technology and products.

3.Our Product:

Our Products includes the following:

1, Crane accessories

2, Electric hoist

3, Single - beam cranes

4, Double - beam cranes

5, Bridge crane

6, Gantry crane

7.Lifting equipment and accessories

We supply crane products all over the globe to a wide range of companies worldwide.

4.Product Application:

The products are widely used in the following industry, such as power plants, nuclear power, water conservancy, tunnels, bridges, petrochemical, metallurgy, construction, open-air warehouse, wharf, workshop ...

5.Our Certificate:

Our company is a member of China Crane Association and vice chairman company of China Heavy Machinery Association. It owns the production licenses of electric hoist, single & double-girder crane, the safety of the approval certificate of manufacturing, installation and maintenance, the safety approval certificate of the manufacturing of 320T bridge crane, Portal Crane and 280Tcasting crane.

The company has passed the quality system certification of GB/T19001 -2008/IS09001:2008, the environmental management system certification of GB/T24001-2004/ISO14001:2004 and the occupational health and safety management system certification GB/T28001-2001.

6.Production Equipment:

There are 1600 units of all kinds of processing equipment which can independently accomplish all the processes such as milling, digging, grinding, pulling, boring, rolling, drilling, punching, cutting, bending, welding, testing and heat treatment.

7.Production Market:

Our products are sold to more than 30 provinces, municipalities and autonomous regions in China, and also exported to Australia, Vietnam, India, Thailand and some Southeast Asian countries. The annual sales of double-girder and portal cranes is more than 3600 units, more than 23000 units single-girder cranes, about 23000 units single-girder & double-girder electric hoist and accessories. The production and sales of the single-girder cranes has lead the nation for seven consecutive years and the per capita output and economic benefits are among the best in the same industry.

8.Our service:

Besides our existing molded products, LITECrane Co., LTD also can produce products according to the drawings or samples from our customers. We control the product quality critically for every step during the manufacturing from custom.

Contact us if you need more details on Tower Crane Parts Hook. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Crane Spare Parts、Tower Crane Spare Parts. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Crane Parts > Hook Group